Open-cell and Closed-cell Urethane (polyurethane) Foam and some differences:

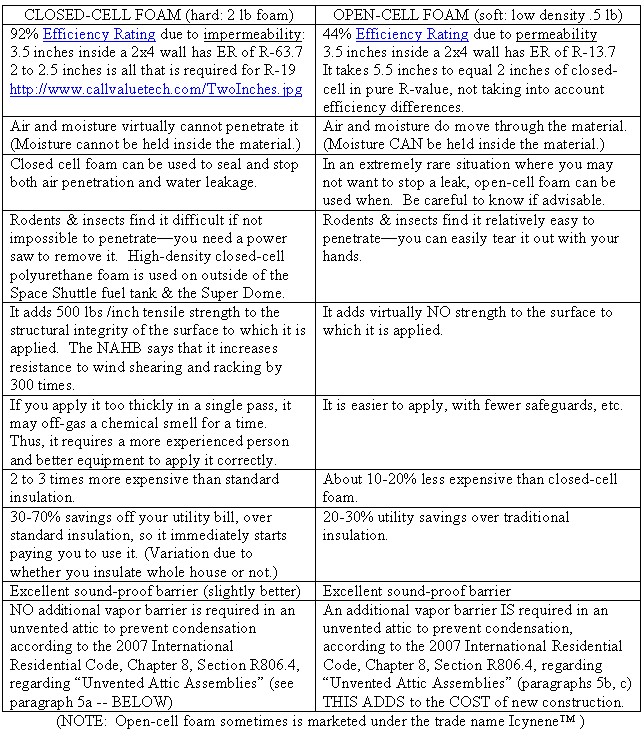

Click here> Efficiency Ratings

Basically, the choice between these two polyurethane foams depends on the requirements of each project or installation. We at Value Tech Insulation routinely select from a variety of foam systems with varying characteristics, depending on the particular requirements of each client's project. We may also develop hybrid systems for your particular application, utilitizing foam in one part of the house, and cellulose or fiberglass (or rock wool, for sound-proofing, etc.) in others.

As the most effective type of insulation, closed-cell Sprayed Polyurethane FOAM (SPF) is a solid, rigid, waterproof, and seamless plastic after it cures (in only a few seconds). It is impervious to liquid or gas penetration. The History Channel describes closed-cell polyurethane foam insulation as one of the "modern marvels" of modern chemistry: It not only insulates, but closed-cell foam also dramatically adds to the strength and structural integrity of any building material. SPF is sustainable: Unlike other materials that have a limited life expectancy SPF has an indefinite life span. Cellulose insulation may have to be enhanced or upgraded every decade, and fiberglass usually disintegrates, blows away, or becomes infested and must be replaced. Both will have to be replaced if infested with rodents, squirrels, or insects. However, if you invest in closed-cell SPF foam you will never have to buy insulation again (for the life of the home or building). It is permanent and does not degrade.

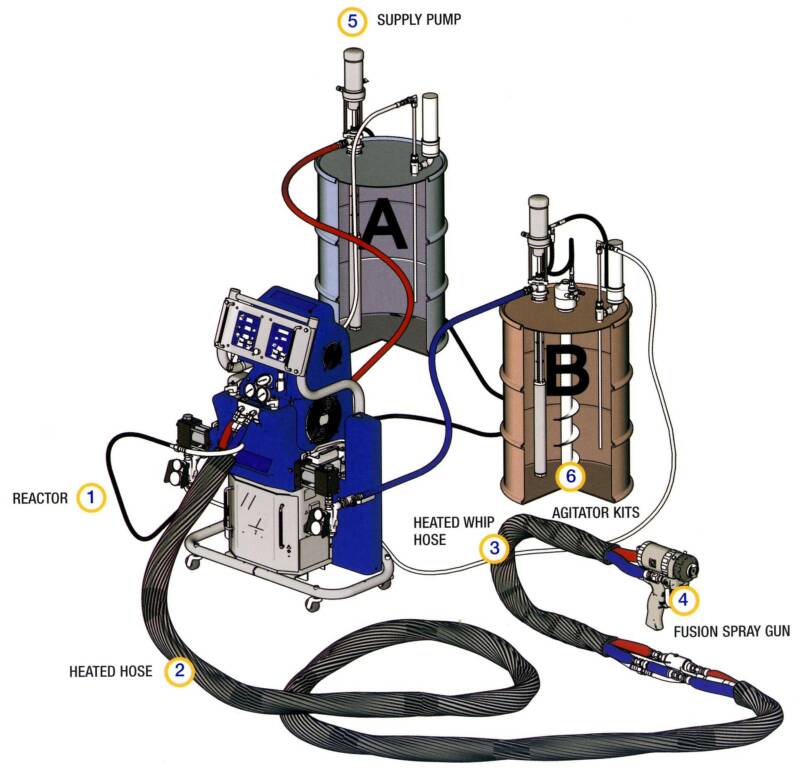

Sprayfoam or spray applied polyurethane foam is applied with special equipment, highly technical and expensive equipment, which exactly proportions and combines two components (like the "A" and "B" components of epoxy glue) into a new compound (polyurethane) through rapid chemical reaction. It does not depend on air to "dry" or cure. The chemical reaction itself is the curing process, and it can even take place under water. The two chemical components are mixed or combined at the very moment they leave the tip of the spray gun, and within 3-5 seconds the chemical reaction is complete-- resulting in cellular plastic. Temperatures, pressures, and thickness must be carefully controlled during the application process, in order to produce the proper quality product, and to avoid handling errors. Special training and years of experience are required to learn how to do it properly. Although the two components can be hazardous in their separate liquid states, the plastic foam that results from the chemical reaction of the two components is inert and harmless. Indeed, air quality and health are two of the main reasons home owners choose SPF foam over other insulations (which can be hazardous AFTER their application). The air-tight monolithic seal created by foam can eliminate dust, radon, mold, and other dangerous elements from the air you may be breathing in your home everyday. (See "stack effect" and pages on mold and dust.)

Open-cell polyurethane foam is soft and spongy (like a cushion). The millions of tiny bubbles in the foam we call cells. When we say "open-cell" we mean thath the cell walls, or surfaces of the bubbles inside the foam, are ruptured or broken and air fills all of the spaces in the material-- no longer contained inside the bubbles. This means that the air-tight seal is broken and air (and moisture) can move through the foam (still more slowly that fiberglass or even cellulose). The rupture of the cell structure makes the foam softer and weaker than closed cell foam, since it no longer has the integrity of closed cells, which create a matrix or honey comb effect. The insulation value of this foam is related to the insulation value of the calm air inside the matrix of broken cells. The densities (weight/volume) of open-cell foams are approximately 1/2 to 3/4 of a pound per cubic foot. Icynene ™ (registered trade name) pertains only to one variety of open-cell foam. Confusedly, some folks simply substitute the term to refer to any (and all) open-cell foam. Sometimes they even substitute the term for polyurethane in general, as if it refers to all foam (BOTH open and closed cell foam). This error is like saying you are going to make a "Xerox" copy, when the machine you use could be any brand of copy machine. Or it is as if you asked someone if they would like a "Coke" or if they want a "Kleenex", when you are only using these terms generically. The reverse is actually true. That is to say, Icynene is just one brand of open-cell foam, and not the generic category for ALL open-cell foam. It is in a completely different category from closed-cell foam, although the trade name is derived from one of the main components found is ALL foam, which is the "A" component, Isocyanate (represented by the RED barrel above). The most common uses for open-cell foam are thermal insulation for vaulted ceilings and attics (barrier sometimes required), and for sound-proofing under floors and walls. ( 5-6 inches is required, compared to 2 inches)

Closed-cell foam has varying degrees of hardness and rigidity, depending on its density. Sometimes it is called "cellular plastic." The cells are full of a special gas, selected to make the insulation value of the foam as high as possible. Its volume as a liquid will expand 30 times during the chemical reaction that turns it to a solid. Typically closed-cell insulation weighs between 2 and 3 pounds per cubic foot. 2 pound foam is what we typically use in homes and most commercial buildings. It is strong enough to walk on without major distortion, and can therefore be used for roofing material-- as covers the Super Dome, for example. Though some of the cells or bubbles in the foam may rupture during the expansion, most are not broken. They resemble inflated balloons or soccer balls, piled together in a compact configuration. This makes it strong or rigid because the bubbles are strong enough to take a lot of pressure, like the inflated tires that hold up an automobile. It is so strong that only 2 inches sprayed in a wall will increase that walls resistence to [sheering and racking in] a wind storm by 300 times, according to the NAHB (National Association of Home Builders). It is so strong that NASA uses it to insulate the Space Shuttle booster tank (insulating liquid hydrogen from the outside air). When properly applied this dense foam can withstand winds and stress in excess of a thousand mile per hour (as with Space Shuttle filght). We find sections of walls ripped from houses by tornados still have the foam on the walls. (See 2 to 2.5 inches is enough in GA. Also How much R-value do different parts of my home require? )

The advantages of the Closed-cell foam compared to open-cell foam include its strength, its higher R-value, and its resistance to the leakage of air or water vapor. Indeed it is often used solely for air sealing -- providing an air-tight seal. The disadvantage of the closed-cell foam is that it is denser, requiring more material, and therefore, more expense. While the open-cell foam is more limited than the closed-cell, for various applications, it is often used as a cost saving measure since it is less expensive than closed cell. As stated above, the most common uses for open-cell foam are thermal insulation for vaulted ceilings and attics (barrier sometimes required), and for sound-proofing under floors and walls. The choice of foam should be based on the requirements for the other characteristics — strength, vapor control, available space, etc. NOTE: Because of its permeability and the possibillity of condensation and mold formation within it, like fiberglass Open-cell foam (such as Icynene®) should NEVER be used in a crawl space.

Both Open and Closed cell foam are commonly used in building applications. Some are inappropriate in specific applications. For example, you typically would not use open-cell foam below grade or on buildings on or near bodies of water especially in the humid tropical climates where it could absorb water; this would negate its thermal performance because water is a poor insulator compared to air. For the same reason (i.e., infiltration) that fiberglass collects moisture and facilitates mold growth in moist basements and crawlspaces, open-cell should not be used in those environments. Likewise, closed-cell foam is preferred where small framing sizes (e.g.,2x4s) need the greatest R-value per inch possible (or when you simply cannot get enough R-value). Both can be used for sound proofing-- closed-cell foam being only slighly better on the higher frequencies. You can download test data by clicking here >> http://panopli.net/ed/ValueTechAcousticalSpecsOPEN.pdf and here >> http://panopli.net/ed/ValueTechAcousticalSpecsClosed.pdf (case sensitive)

The "A" component consists of 55 gallons of a compound known for its high reactivity:

Di Isocyanate

The "B" component consists of 55 gallons of a mixture of compounds, consisting of polyols, resins, blowing agents, and surfactants..

See Glossary

NOTE: One brand of open-cell foam is sold under the trade name Icynene™. There is nothing special about it, compared to other open-cell foams. Milks is milk. Gasoline is gasoline. All basically the same. See paragraph on open-cell below.

Click here

Helping the "Building Green" revolution of energy savings for the planet and the pocket.

See U.S. Government "Green Home" building programs.

Click here

See History Channel's video on foam "Modern Marvel" ( 23 MB download)

Serving Metro Atlanta and the Southeast U.S.

770-981-9090

Fax: 678-691-7828

Free estimates

Email: info@callvaluetech.com

Closed-cell versus Open-cell FOAM

Back to TOP << click here

Back to TOP << click here

Back to MAIN foam page << click here

See PDF (download)

Closed-cell works best here

Either Open-cell or Closed-cell will work here

: 1/2 lb)

We did the house below with both open and closed-cell foam. Closed-cell was used only in the crawlspace, and outside.

Open-cell foam was used in the ceiling and walls

│

│

│

│

│

│

│